Reciprocating Compressor

Sour gas compressor /Purge gas/ oil free compressor

The reciprocating compressor is one of the most widely used compressors in petrochemical complexes, refineries, and processes related to natural gases. Therefore, Havayar has always tried to support its customers by producing and supplying reciprocating compressors which have the highest quality that require minimum maintenance in the long term.

Sour gas compressor /Purge gas/ oil free compressor

The reciprocating compressor is one of the most widely used compressors in petrochemical complexes, refineries, and processes related to natural gases. Therefore, Havayar has always tried to support its customers by producing and supplying reciprocating compressors which have the highest quality that require minimum maintenance in the long term.

The reciprocating compressor is one of the most widely used compressors in petrochemical complexes, refineries, and processes related to natural gases. Therefore, Havayar has always tried to support its customers by producing and supplying reciprocating compressors which have the highest quality that require minimum maintenance in the long term.

A reciprocating compressor is easily used in a variety of applications, while any other type of compressor may be more suitable for a particular application. For example, centrifugal compressors are commonly used when power consumption is above 2 MW, gas molecular weight above 10 and gas outlet pressure less than 100 MPa. Also screw compressors are preferred in the power range between 10 and 500 kW and outlet pressure less than 30 bar. Piston compressors have good efficiency because the piston rings perform good sealing and also very low heat transfer makes the efficiency of this type of compressor very close to isentropic. In low-speed compressors, the efficiency of 85-95% is easily achievable, and in high-speed compressors, this value ranges from 80 to 90%. Mechanical efficiency, which is caused by friction and structural losses, is usually 95 to 98%. From the point of view of efficiency, other types of positive displacement compressors actually have lower efficiency and more leakage. One of the advantages of all positive displacement compressors is their operation with different types of gases and even variable density, and the reciprocating compressor is also in this group. Compared to centrifugal compressors, these compressors have higher maintenance costs and take up more space. But instead, they are much more efficient and produce higher range of output pressure. Centrifugal compressors use more power to pressurize low molecular weight gases, which is why hydrogen compressors are usually reciprocating type.

Types of air piston compressors

Air Reciprocating compressor is designed according to API 618 standard, the latest version. They also comply with many international construction guidelines and codes and customer requirements.

API reciprocating compressors

This type of piston compressors are manufactured in accordance with the API 618 standard, for this reason they have specific material requirements and a lower speed than CNG compressors (usually lower than 600 rpm). Havayar Industrial group manufactures API piston compressors mainly in three types:

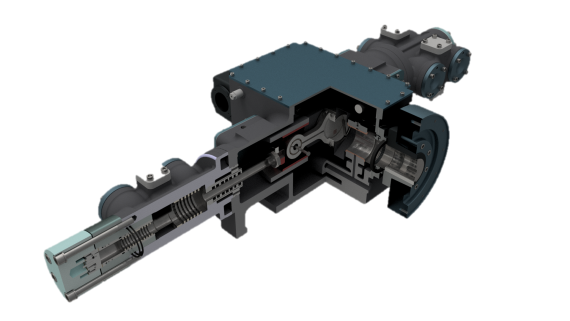

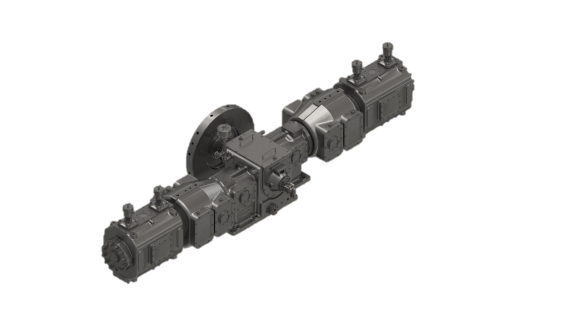

API piston compressors horizontal model (Balanced Opposed)

These types of compressors are the most common types of piston compressors that are installed horizontally. Horizontal piston air compressors are able to provide pressure range from 2 to 1000 bar. The power range of these compressors is from 100 to 3000 horsepower and their capacity range is from 500 to 50,000.

In this type of configuration, two and four throws have a small amount of imbalance, but in the case of six throws, complete balance is established. Usually, when an odd number of steps is needed, a step without work and only including weight is considered. This configuration is employed in all high and low speeds.

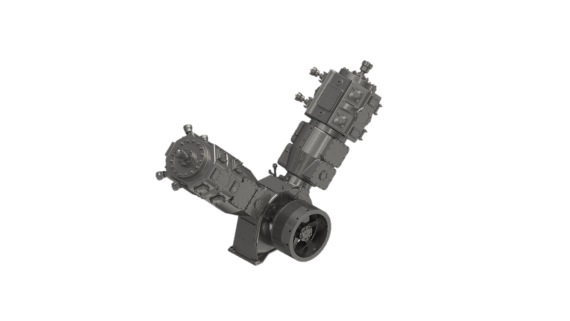

API Y-type piston compressors

This type of compressors occupies less space than horizontal compressors and is usually employed for applications related to nitrogen, hydrogen or air. Air Y-type piston compressors are able to provide pressure from 2 to 150 bar. The power range of these compressors is from 30 to 450 horsepower and their capacity is from 100 to 10,000.

API piston compressors vertical model (Balanced Opposed)

Vertical compressors are usually used in dry gas applications because the vertical structure reduces the possibility of liquid leakage. These types of compressors occupy less space on the surface and are used for low powers. Vertical air compressors are able to provide pressure from 2 to 35 bar. The power range of these compressors is from 5 to 100 horsepower and their capacity is from 25 to 430.

Frequently Asked Questions

- Proper construction

- Minimum vibration

- Maximum efficiency

- Easy operation and maintenance

- Easy installation

- Hard box design

- Cast iron

- Oil tank – bottom side

- Firmly fixed by strong bolts

- Insulated with gasket

- Crosshead guide

- Main oil pump

sales department

after sales service

datasheet

catalogue