Cold Box

Cold box is a complete package of brazed aluminum heat exchanger contained in carbon steel casing with structural support, insulation containment, and protection for the internal equipment. Insulation work of heat exchanger and piping assembly can be easily done by perlite insulation and inside of cold box will be pressurized and purged by dry nitrogen gas.

Cold box is a complete package of brazed aluminum heat exchanger contained in carbon steel casing with structural support, insulation containment, and protection for the internal equipment. Insulation work of heat exchanger and piping assembly can be easily done by perlite insulation and inside of cold box will be pressurized and purged by dry nitrogen gas.

- Heat Exchanger

- Rectification Column

- Joule–Thomson

- Turbo Expander

- Condenser

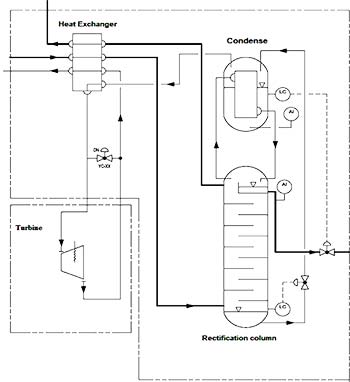

Purified Compressed Air first enters the main heat exchanger in the cold box compartment and is cooled to the liquefaction temperature. The Heat Exchanger used in this package is Aluminum Plate Fin, which has the advantages of light weight, low temperature difference and transmission Heat is very efficient. This flow enters the bottom of the distillation tower. Rectification Columns use the difference in boiling point to separate the components. The oxygen-rich liquid air exits the bottom of the distillation tower and is then expanded by the pressure relief valve and enters the condenser. Also, the pure nitrogen gas (output product from the top of the tower) enters the condenser. The Cold needed to liquefy the nitrogen gas, as the production of the pure liquid nitrogen product, as well as providing the reflux of the tower, is provided by the Heat Exchange between nitrogen and oxygen-rich liquid air.

For the lack of required cold in the process, all or part of the gross residual gas (Waste N2) resulting from the heat transfer in the condenser is expanded in a turbo expander and after passing through the main heat exchanger, it is removed from the cold box, which is used to regenerate the desiccant (Molecular Sieve) available in the molecular sieve system of the drying unit is used.

At the end, the Nitrogen gas enters the heat exchanger from the top of the distillation column and is heated, and finally it is delivered to the consumer as a gaseous nitrogen product with the desired purity. Also, pure liquid nitrogen is removed from the condenser and stored in the storage tank for use.

LNG Cold Box

LNG cold box, applied in natural gas liquefaction plant, is to liquefy and purify natural gas. If nitrogen content in natural gas is more than desirable, nitrogen removal column shall be set to purify natural gas.

Liquid Nitrogen Cold Box

Liquid nitrogen washing cold box is mainly applied in the purification process for fertilizer industry.

ASU Cold Box

ASU Cold Box is the core of air separation unit.

Propane Dehydrogenation Propylene (PDH) Cold Box

Propane dehydrogenation (PDH) is a strong heat absorption process, which can produce a good propylene yield under high temperatures and relatively low pressure. Often propylene and ethylene are used in the propane dehydrogenation (PDH) process to realize gradual cooling and separate olefins.

MTO/MTP Cold Box

MTO (Methanol to Olefins) and MTP (Methanol to Propylene) are two new important processes for methane chemical industry. It is a chemical technology, using methanol synthesized from coal or natural gas as raw material, with a fluidized bed reaction which is similar to catalytic cracking unit, producing low carbon olefins. The cryogenic separation section of olefin separation uses a multi – stream Cold Box.

Carbon Monoxide Cold Box

Carbon monoxide is an important chemical raw material which can be used for the synthesis of a variety of high value added products, such as acetic acid, acetic anhydride, formic acid, dimethyl form amide, light gas and metal carbonyl compounds, etc. To get high purity carbon monoxide, cryogenic separation process could be used. Cryogenic separation is to separate various components based on their different boiling points. According to the different contents in carbon monoxide, we use different combinations to realize separation and purification.

Package Features

- Design Temp: -269oC Up to 93oC

- Design Pressure: Up to 130 bar

- Easy Maintenance

- Full Automation & Remote Control

- Based on International Standard such as: ASTM, ASME, ANSI, DIN and EN

- Low Weight Aluminum Design

- Low Pressure Drops

- Highly Efficient Heat Transfer

- Very Compact Design in Comparison with Conventional Heat Exchanger Type

Frequently Asked Questions

Cold box is a complete package of brazed aluminum heat exchanger contained in carbon steel casing with structural support, insulation containment, and protection for the internal equipment. Insulation work of heat exchanger and piping assembly can be easily done by perlite insulation and inside of cold box will be pressurized and purged by dry nitrogen gas. SPP’s cold box can minimize the installation space at the commissioning site by providing the complete unit package of heat exchanger and piping assembly. Also, cold box can be easily installed and easy access to connection piping will reduce the installation work at pre-commissioning.

Cold Boxes are cryogenic thermal sets that are used in the air separation unit. This thermal set is placed inside the carbon steel metal frame, which is insulated with PERLITE. This section includes the following main equipment: Heat Exchanger, Rectification Column , Joule–Thomson, Turbo Expander, Condenser

sales department

after sales service

datasheet

catalogue