havayar screw compressor

havayar screw compressors are designed to be installed and operated at a low cost. Supporting customers and providing sales and after-sales services is the belief and work policy of the compressor team of Havayar Company.

Contents

what is a screw compressor?

The rotary screw compressor is a displacement compressor type where rotating screws are used to compress the air. Compared with a piston compressor, the screw compressor compresses air continuously without pulsation. It has high efficiency at full load and low efficiency when partially loaded.

Rotary screw air compressors are designed to produce a consistent flow rate which is ideal for a variety of industrial applications. Popular applications include, small machine shops, food & beverage production, automotive manufacturing, pharmaceutical, etc. Rotary screw air compressors are ideal for industrial and commercial businesses because of the durability, efficiency and energy savings. Whether you are in need of an air compressor with direct or belt driven, fixed or variable speed, low or high horsepower and CFM, Havayar screw compressor has a comprehensive selection of models to choose from.

Visit our Product Page to discover our full range of rotary screw air compressor products, and learn more about how our technologies best suit your application needs.

How do rotary screw air compressors work?

When it comes to modern industrial machinery, the rotary screw compressor is one of the most widely used technologies. Renowned for their reliability and versatility, screw compressors are the workhorse behind many industrial processes and applications. This durable technology is suited to an array of demanding industry tasks, without which, businesses around the world would encounter operational challenges and efficiency problems.

There are two basic principles of compression in air compressors. One of these is the principle of positive displacement. There are a lot of compressor types that use this method, screw compressors being the most popular.

Operating Principles

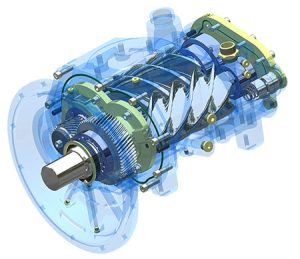

As the name suggests, rotary screw compressors use rotary movements to compress the air. Within the compressor, there is a set of male and female rotors. They will be designed differently so that, when turned in unison, air will become trapped between them. The male rotor has convex lobes and the female rotor has concave cavities; in this way, they can mesh together without touching to achieve compression. Additionally, the male rotor will have slightly less lobes than the female, meaning it will rotate more quickly, effectively driving the female rotor.

Unlike piston compressors which use the same principle of compression, the screw element is not equipped with valves. As such, it can work at a high shaft speed and there are no mechanical or volumetric losses to create imbalance. This means that screw technology can combine a large flow rate with a compact, space-saving design.

What are the benefits of rotary screw air compressors?

As the technology of choice across a wide range of applications, screw compressors have a lot to offer customers:

Continuous operation

Capable of continuous airflow and Pressurization, they don’t need to be shut on and off and have no duty cycle. This means that they can operate continuously with little to no downtime.

Easy to maintain

With very little moving and contacting parts, wear and tear are minimized. Long service intervals drive down maintenance costs and make any routine checks and repairs quick, easy, and hassle-free.

Powerful performance

Screw compressors can operate in challenging conditions as they have high airflow rates and can perform at extreme temperatures. This means they can run pneumatic tools and heavy equipment easily and efficiently.

Energy-efficient

Having stood the test of time, these durable machines produce less heat and conserve more energy than other models. These design features mean that they offer zero loss of capacity over time, keeping the lifetime cost of the compressor low.

Low noise

Quiet operation is down to the small size of the units and the lack of moving parts, making them suitable for point of use installations.

Frequently Asked Questions

The rotary screw compressor is a displacement compressor type where rotating screws are used to compress the air. Compared with a piston compressor, the screw compressor compresses air continuously without pulsation. It has high efficiency at full load and low efficiency when partially loaded.

When it comes to modern industrial machinery, the rotary screw compressor is one of the most widely used technologies. Renowned for their reliability and versatility, screw compressors are the workhorse behind many industrial processes and applications. This durable technology is suited to an array of demanding industry tasks, without which, businesses around the world would encounter operational challenges and efficiency problems.

Like any other compressor, the screw compressor has its own types. Of course, it should be noted that the manufacturing companies divide this compressor into different types according to their policy, for example, some group them based on the size of the tank or some based on the drive system of the gears. In general, there are two types of havayar screw compressors, which are:

oil injected screw compressor

Our screw compressors are designed to be installed and operated at a low cost. Supporting customers and providing sales and after-sales services is the belief and work policy of the compressor team of Havayar Company.

Oil Free Screw Compressor

Oil Free Screw Compressors are usually employed in critical applications. The phrase “critical application” refers to the situation where air quality is regarded very important for the production process and the final product.

CONTACT US

In order to defend the rights of customers and to respond to their demands and needs, Havayar has set up a communication unit with customers.