Refrigeration Package

Havayar work on refrigeration package for the full range of sectors within modern industry such as processing and storing food or Oil and Gas, beverages, chemical/ Petro-chemical and others.

Havayar engineering team develops company standards for design of refrigeration package and component utilizing various computer-aided program & software.

Your special requirements and specification can be implemented into our design

Havayar work on refrigeration package for the full range of sectors within modern industry such as processing and storing food or Oil and Gas, beverages, chemical/ Petro-chemical and others.

Havayar engineering team develops company standards for design of refrigeration package and component utilizing various computer-aided program & software.

Your special requirements and specification can be implemented into our design

Havayar work on refrigeration package for the full range of sectors within modern industry such as processing and storing food or Oil and Gas, beverages, chemical/ Petro-chemical and others.

Havayar engineering team develops company standards for design of refrigeration package and component utilizing various computer-aided program & software.

Your special requirements and specification can be implemented into our design.

Design and Manufacturing Capability

Havayar fabricate various products from refrigeration components to engineered package units acc. to customer’s specification such as Ammonia Refrigeration package, Chilled Water Refrigeration Package, Propylene Refrigeration Package, Propane Refrigeration Package for HDPE & PP Plant project and etc.

Including Compressor unit, Condenser, Evaporator, Receiver, Economizer, Liquid separator, Local gauge board and Control panel.

Features

- Designed by professionals in the field of process and industrial refrigeration.

- Based on Screw, reciprocating and Turbo Compressor

- The latest technological advances provide the greatest efficiency, simplicity of operation, reliability and lowest operating cost.

- Installation and start-up is by our own team of factory experts.

- Refrigerant piping and welding is in accordance with all applicable ASME and local codes.

Process Chilling Package

- Liquid Chiller

- Gas Chiller

- Brine Chiller

- Water Chiller

- Boil Off Gas Condensing Package

Application Code & Design: API 619, TEMA 9th Edition, ASME Section VIII Div.1 2010 Edition, KGS / KOSHA

Engineering Tools: HTRI, COMPRESS, AutoCAD (2D), Invertor (3D)

Refrigeration systems are commonly used in process industries related to natural gas and related refinery and petrochemical industries to cool various process fluids. For example, we can mention NGL processes, LPG recovery and dew point control of hydrocarbon compounds and LNG facilities. In general, the selection of refrigeration systems is based on the required temperature, availability, economic issues, and previous experiences. For example, in natural gas processing facilities, ethane and propane are used, while in olefin units, ethylene and propylene will be used. Propane and propylene are not suitable in ammonia facilities due to the possibility of contamination, and ammonia is used as a refrigerant in these facilities.

Refrigeration package or chiller is a device that is used to cool hot fluid. This cooling can be done directly by refrigerant gas or an intermediate fluid, which is usually water or a mixture of water and glycol. Among the types of refrigeration cycles, we can mention the absorption refrigeration cycle and the condensation refrigeration cycle.

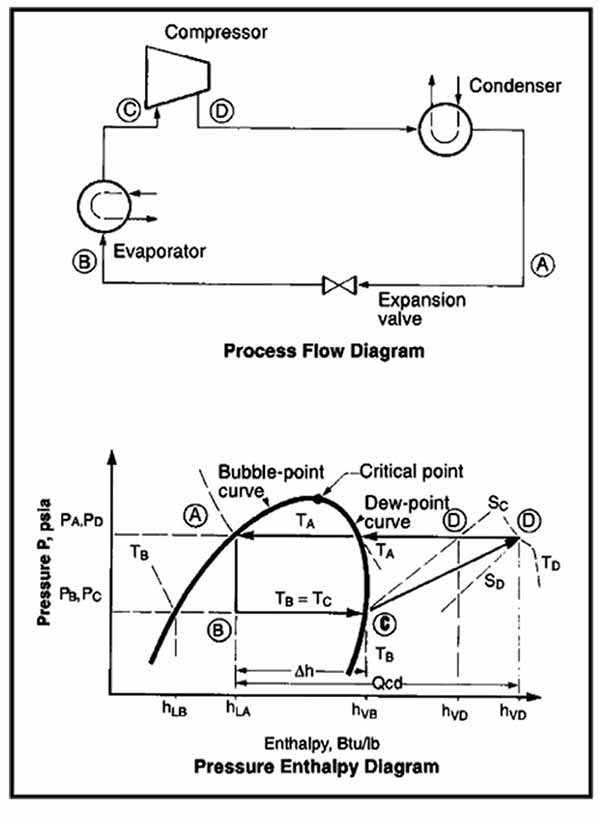

According to the pressure-enthalpy diagram, the condensation refrigeration cycle can be divided into the following 4 stages:

1- Expansion or expansion valve

2- Evaporation

3- Compression

4- Condensation or liquefaction

The steps mentioned above can be shown as in Figure 1:

- Expansion stage

The starting point of the refrigeration cycle is the availability of the refrigerant liquid. Point A in Figure 1 represents the liquid bubble point at saturation pressure, PA and enthalpy hLA. In the expansion phase, the temperature and pressure decrease to PB, due to the liquid passing through the valve and the occurrence of sudden evaporation or flashing. The low pressure PB is determined by determining the coolant temperature TB (point B).

- Evaporation stage

The steam produced in the expansion process (A-B) will not provide any cooling to the process. The cooling process occurs in a heat exchanger called an evaporator, and heat is transferred from a hot fluid to a cold fluid. As shown in Figure 1, this process occurs at constant temperature and pressure (B-C). Therefore, the enthalpy of steam at point C is equal to hVB. This stage is also called chiller because cooling of the process fluid takes place in this stage.

- Condensation stage

The refrigerant vapor coming out of the evaporator (chiller) is at the saturated vapor point PC, whose temperature and corresponding saturation enthalpy are equal to TC and hVB. According to Figure 1, the entropy at this point is equal to SC. Refrigerant vapor condenses is entropically to the pressure PA. This process is shown along the line C-D in Figure 1. The driving force of the compressor can be an electric motor, an internal combustion engine, a turbine or… Among the mentioned cases, the use of electric motors is more useful than other cases. The compressors used in the compression refrigeration cycle can be reciprocating (piston), screw, scroll and centrifugal.

- Liquefaction stage

Refrigerant in the super-hot state at the pressure PA and TD is taken out of the compressor (point D in Figure 1) and in the process of constant pressure (almost constant pressure) it cools down to the saturation temperature TA and the refrigerant vapor becomes liquid at a constant temperature. During this process, all the heat and work done during the evaporation and condensation processes must be removed from the system, and the refrigeration cycle is completed by reaching point A again.

Frequently Asked Questions

Refrigeration systems are commonly used in process industries related to natural gas and related refinery and petrochemical industries to cool various process fluids. For example, we can mention NGL processes, LPG recovery and dew point control of hydrocarbon compounds and LNG facilities.

In general, the selection of refrigeration systems is based on the required temperature, availability, economic issues, and previous experiences. For example, in natural gas processing facilities, ethane and propane are used, while in olefin units, ethylene and propylene will be used. Propane and propylene are not suitable in ammonia facilities due to the possibility of contamination, and ammonia is used as a refrigerant in these facilities.

Refrigeration package or chiller is a device that is used to cool hot fluid. This cooling can be done directly by refrigerant gas or an intermediate fluid, which is usually water or a mixture of water and glycol. Among the types of refrigeration cycles, we can mention the absorption refrigeration cycle and the condensation refrigeration cycle.