Our integrally geared type compressor cover your needs, typically stand for high efficiency and reliable performance and these compressors are designed based on API 617 (chapter-3).

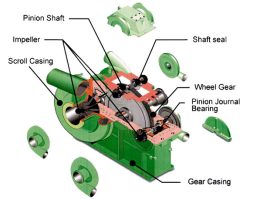

Integrally geared compressors are multi-shaft machines. Several pinion shafts with one or two impellers each are arranged around a central bull gear. For each pinion shaft a perfect combination of shaft speed and impeller size can be realized. All impellers are of overhung design and can be fitted with adjustable inlet guide vanes in front of each impeller. Inter-stage cooling of the gas stream can be done after each impeller discharge. The combination of these features allows for high volume flows, outstanding energy efficiency even under part load, all in a compact design.

Applications

- Air Separation

- Carbon Capture, Utilization and Storage

- Compressed Air Energy Storage (CAES)

- Fertilizer

- Fuel Gas

- Heat Pumps and Refrigeration

- Petrochemicals

- Refining

- Synthetic fibers (PTA, DMT, Caprolactam)