oil bearing turboexpander

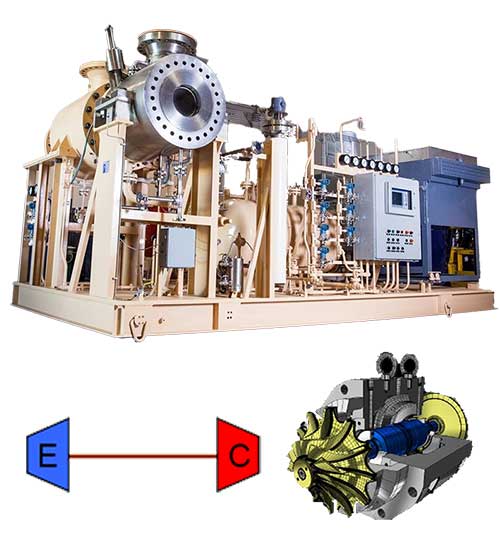

One of the most important reasons for using oil bearings in some applications is the lower complexity and, as a result, the lower cost of this equipment. Unlike magnetic bearings (Active Magnetic Bearing), which have very limited manufacturers, oil bearings are produced by more manufacturers worldwide. Also, it has a simpler structure and easier repairs, and its installation does not require the requirements of AMBs (like the AMB panel, etc.). Air separation plants are one of the main application areas of turboexpander with oil bearing.

One of the most important reasons for using oil bearings in some applications is the lower complexity and, as a result, the lower cost of this equipment. Unlike magnetic bearings (Active Magnetic Bearing), which have very limited manufacturers, oil bearings are produced by more manufacturers worldwide. Also, it has a simpler structure and easier repairs, and its installation does not require the requirements of AMBs (like the AMB panel, etc.). Air separation plants are one of the main application areas of turboexpander with oil bearing.

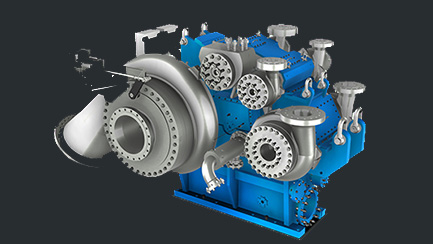

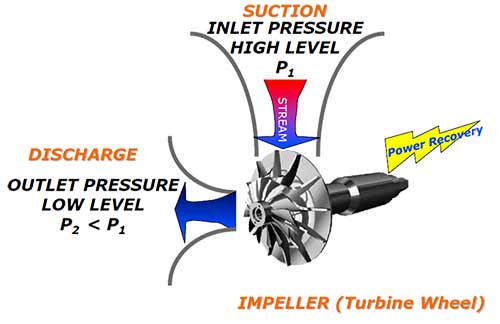

The turboexpander is a rotating equipment, of which the radial turbine is an integral part, and like other turbines, it is responsible for converting the energy in the gas into mechanical work. But there is main difference between turboexpander and other turbines. i.e., steam turbines and gas turbines convert mechanical work into useful power. But in this equipment, the goal is to expand the gas and consequently reduce the temperature, and mechanical work is produced as a byproduct.

Of course, this does not mean that this by-product is not profitable. Rather, if this power is used as a drive for a compressor, the efficiency of the plant will increase significantly.

Turboexpander applications

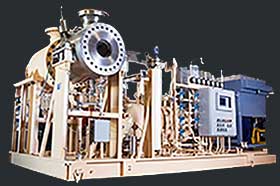

One of the most common applications of turboexpanders is in cryogenic applications and for liquefaction of natural gas. Also, this type of expanders is used in the petrochemical industry and for ethylene, separation, refrigeration and power generation plants.

Two major markets for turboexpanders are hydrocarbon processes and air separation plants. In both cases, the goal is to bring the process gas conditions to a certain pressure and temperature. Expanders reach the mentioned goal by expanding large amounts of gas and consequently reducing its temperature. Therefore, in a way, it can be said that expanders are also considered equipment for refrigeration.

Oil bearing or magnetic

One of the most important reasons for using oil bearings in some applications is the lower complexity and, as a result, the lower cost of this equipment. Unlike magnetic bearings (Active Magnetic Bearing), which have very limited manufacturers, oil bearings are produced by more manufacturers worldwide. Also, it has a simpler structure and easier repairs, and its installation does not require the requirements of AMBs (like the AMB panel, etc.). Air separation plants are one of the main application areas of turboexpander with oil bearing.

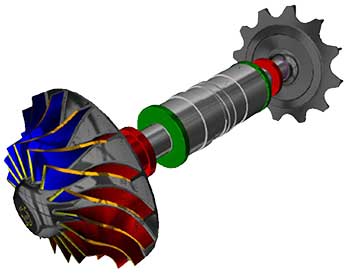

Apart from bearing the weight of the rotor (and other radial forces), the bearings must also overcome the axial forces generated in the turbine or compressor. The main reason for these axial forces is the pressure difference between the wheels of the turbine or compressor. In many cases, the axial force on the turbine side is close to the compressor part and in the opposite direction. But due to fluctuations in gas performance conditions, we expect that the amount of this axial resultant force and even its direction will change. To solve the problem and overcome the resulting axial force, expanders are usually composed of two radial-axial bearings (compound). Radial bearings can be tilting pad or fixed geometry. Axial bearings are usually of the taper land type so that they can withstand the axial force well.

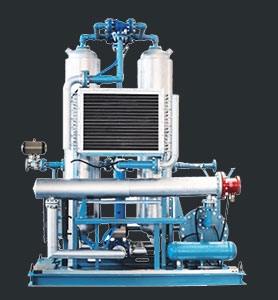

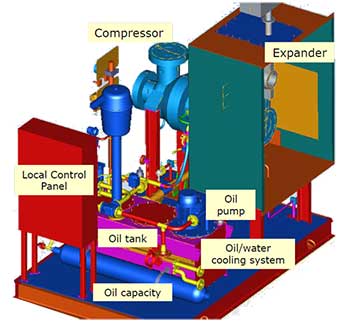

Due to the fact that these bearings require clean and cool oil, in oil bearing expanders, a closed-circuit oil system (lube oil system) is usually required, which is selected according to the API 614 standard. This oil circuit at least includes cooler, filter, pump, pressure safety valve and temperature control valve.

It should be noted that this oil circuit is installed on the main skid of the compressor in most applications, but there are also cases where we have a separate skid called Lube Oil Skid.

With all the above explanations, in many petrochemical plants, turboexpanders with magnetic bearings (Active Magnetic Bearing) are preferred to oil bearings.

Havayar is the leader in the production of turboexpanders

As the first manufacturer of low-size turboexpanders in Iran, with the participation of prominent international manufacturers, Havayar has become a reliable partner for employers in the oil, gas and petrochemical industries.

Also, now, different types of these expanders, both oil bearing and magnetic bearing, are supplied by this company in partnership with famous international manufacturers in different sizes and capacities, and they are being used in many active plants in the country.

Frequently Asked Questions

The turboexpander is a rotating equipment, of which the radial turbine is an integral part, and like other turbines, it is responsible for converting the energy in the gas into mechanical work. But the main difference between turboexpander and other turbines is that steam turbines and gas turbines convert mechanical work into useful power. In this equipment, the goal is to expand the gas and consequently reduce the temperature, and mechanical work is produced as a byproduct.

Two major applications for turboexpanders are hydrocarbon processes and air separation plants. In both cases, the goal is to bring the process gas conditions to a certain pressure and temperature. Expanders reach the mentioned goal by expanding large amounts of gas and consequently reducing its temperature. Therefore, in a way, it can be said that expanders are also equipment for cooling.

sales department

after sales service

datasheet

datasheet

catalogue