PSA Package

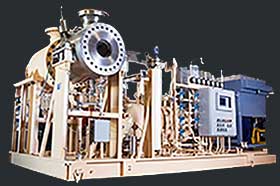

Havayar Industrial Group is able to engineer, supply, install, set up and maintain PSA Package (oxygen, hydrogen and nitrogen) with different capacity and purity.

Contents

What is Pressure Swing Adsorption (PSA) Technology

Pressure Swing Adsorption or PSA is an economic and reliable method used to separate mixed gas into individual gases while achieving a high purity level. PSA is a non-cryogenic air separation process which essentially means it is a process which uses near ambient temperatures for the production of nitrogen or oxygen in contrast to the cryogenic distillation techniques of gas separation which take place are very low temperatures and is a process commonly employed in chemical and petrochemical processes in commercial practices.

During the process, gases are separated under pressure based on the species molecular characteristics and affinity for an adsorbent material. PSA is used to recover hydrogen from coking or conversion gases or to split oxygen and nitrogen from the air.

The Principle of Pressure Swing Adsorption

In pressure swing adsorption, specialize adsorbent materials adsorb the gas molecules such as oxygen, carbon dioxide, water vapour and other gases under high pressure with the exception of nitrogen. PSA systems for oxygen production were first used during the 1970’s and since then the technology has overall shown rapid improvement.

Before getting into the process of how the PSA Package works it is essential to understand the difference between adsorption and absorption. The Pressure Swing Adsorption separation system is based on the principle of adsorption. Adsorption is a surface-based procedure while absorption involves the whole volume of the material. The adsorption method is when the gas or liquid molecules adhere on the surface of the adsorbent. This process creates a film of the adsorbate on the surface of the adsorbent.

Each PSA system uses specialized adsorbent materials such as zeolites, molecular sieves, activated carbon etc. These substances are used as a trap, ideally adsorbing the target gas species at high pressure. The process then swings to low pressure in order to desorb the adsorbed material hence the name pressure swing adsorption. This adsorption process is based upon the gas molecules binding to these absorbent materials, preferably only the gas, which is to be absorbed, while all other gases in the mixture pass through the adsorbent bed.

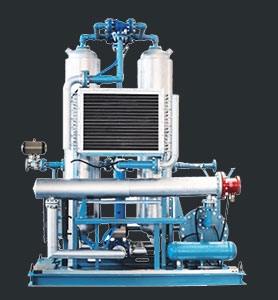

The Process

A PSA Package essentially consists of two or more adoption towers filled with absorbent materials, filters, and a storage tank. One of the benefits of a PSA system is that you can stabilize the purity of the gas. This is done by the manufacture of the generator based on 2 main points: The number of absorbent materials in the tower and amount of time the air is in the towers. Of course, the quality of the materials used will also have an effect on the purity of the gas produced.

Havayar’s PSA generators use Carbon Molecular Sieves (CMS). The quantity of the CMS required for the generators is based on a number of factors such as the purity required, contact time, cycle time, velocity, and temperature. CMS is generally known to be a strong and chemically inert material and are cylindrical in shape, this is intentional in order to obtain a high surface to mass ratio.

How It Works

Gas enters the inlets and is passes through pre-filters and removes any water from the gas, the compressed purified air then passes through onto the adsorption towers. Predominantly oxygen is adsorbed on the carbon molecular sieve (CMS) and nitrogen enriched gas passes on from the tower into the storage tank of the generator.

The concentration of the oxygen can be reduced to meet required purity levels. During adsorption in one tower the second tower is totally regenerated just by depressurisation to ambient pressure. Regeneration can also be referred to as “purging” and is the process in which the gases with the exception of nitrogen is accumulated during the cycle being stripped away. The Oxygen enriched off gas is then vented to the outside atmosphere and after so many minutes adsorption in one tower switches over to the second tower and the first one is regenerated.

Frequently Asked Questions

PSA is an economic and reliable method used to separate mixed gas into individual gases while achieving a high purity level.

A PSA System essentially consists of two or more adoption towers filled with absorbent materials, filters, and a storage tank. One of the benefits of a PSA system is that you can stabilize the purity of the gas. This is done by the manufacture of the generator based on 2 main points: The number of absorbent materials in the tower and amount of time the air is in the towers. Of course, the quality of the materials used will also have an effect on the purity of the gas produced.

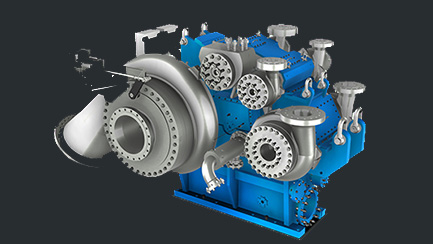

PSA Oxygen Unit

Ambient air contains 21% oxygen, 78% nitrogen, 0.9% argon and 0.1% rare gases. Meanwhile, the production of high purity oxygen gas is of particular importance as one of the most important industrial gases.

PSA nitrogen unit

Today, quality nitrogen production is of particular importance as one of the most widely used industrial gases. This gas plays a key role in petroleum refining industries.

PSA Hydrogen Unit

Hydrogen is the most abundant element in nature with various applications in industry. Hydrogen can be found in most substances such as water, fat, oil, etc. Also, hydrogen is used as a clean fuel of the future.

CONTACT US

In order to defend the rights of customers and to respond to their demands and needs, Havayar has set up a communication unit with customers.