Today, different companies in various industries such as petrochemical, refinery, chemical, cement, steel, and transportation sectors in Iran are using Single Shaft Centrifugal Compressors supplied by Havayar..

These types of compressors, which are among the most popular compressors in the oil and gas industry, are classified in the following categories:

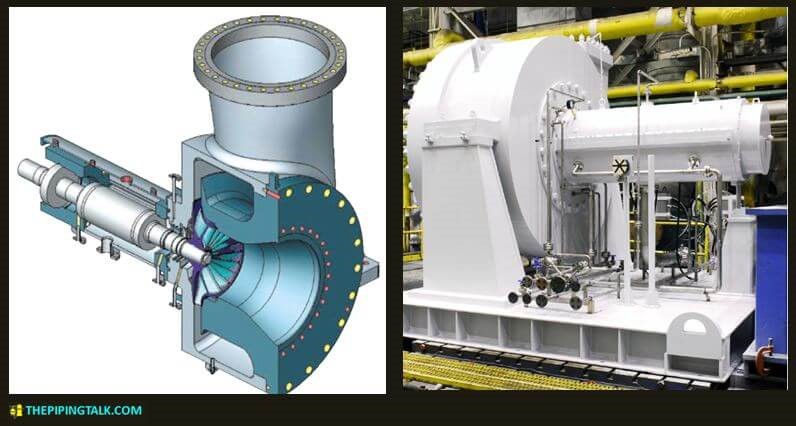

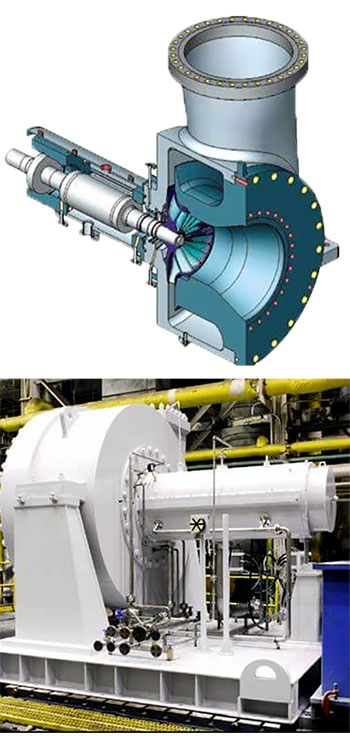

Overhung Single Shaft Single Stage Centrifugal Compressor

Single-stage centrifugal compressors, as the name suggests, have an impeller, a diffuser, a volute and an IGV. These types of compressors, depending on the fluid inside, are able to provide a pressure ratio of 3.5 for each stage. Also, its flow rate can change from the range of 1700 m3/hr to very high flow rates, even close to 500,000 m3/hr.

Single-stage overhung compressors are one type of centrifugal compressor for low pressure and high flow rates. In the oil and gas industry, these sorts of compressors are more limited. The impeller of this type of compressor is placed on the opposite side of the motor (NDE). Because of the axial suction of the flow, overhung compressors have a relatively high efficiency and a wide flow range. These compressors can handle flow rate and pressure ratio up to 3.5 bar. The main difference between these compressors and single-stage Integrally Geared compressors is that the gearbox is positioned outside the casing assembly. Overhung compressors are mostly used in coke gas services.

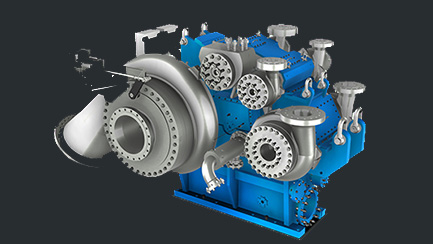

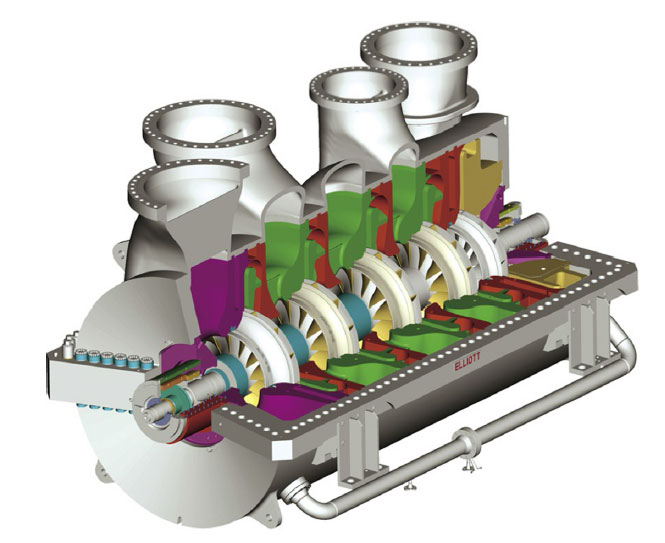

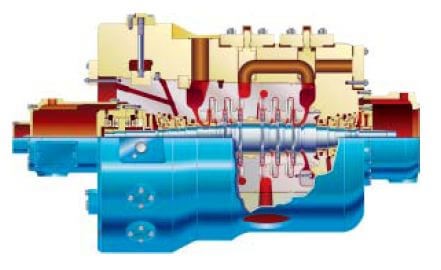

Multi-stage Single Shaft Centrifugal Compressor with horizontal shell cutting

Among the different types of centrifugal compressors, this model is particularly popular in the industry. These types of compressors are used for applications with a working pressure of less than 60 bar and consist of two half-cylindrical casing parts which are assembled with bolts and nuts.

Due to sealing issues and bolting limitations, these compressors cannot be used for very high pressures. Almost all the piping connections of this type of compressors are located in the lower part of the compressor.

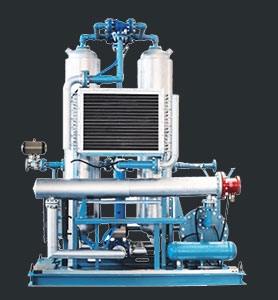

Multi-stage Single Shaft Centrifugal Compressor with vertical shell cutting

This type of centrifugal compressor, like the preceding one, has a cylindrical shape and is known as barrel compressors due to the vertical incision in the casing. Unlike the previous type, these compressors can withstand extremely high pressures. Because of their one-piece structure and presence of sealing, these compressors can withstand pressures up to 680 bar.

Multi-stage centrifugal compressor with bell-shaped casing

This type of compressor is named bell shaped because of the appearance of their casing. In this type, rings surround the casing, which can allow the compressor shell to withstand higher pressures.

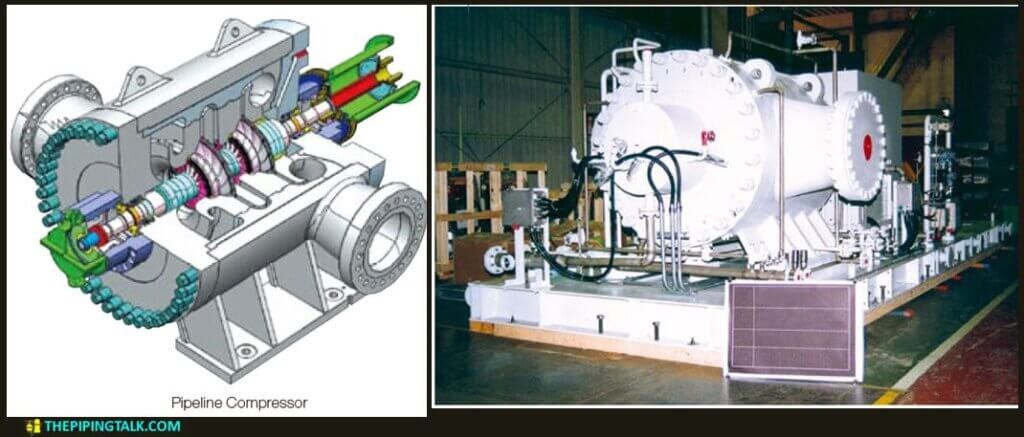

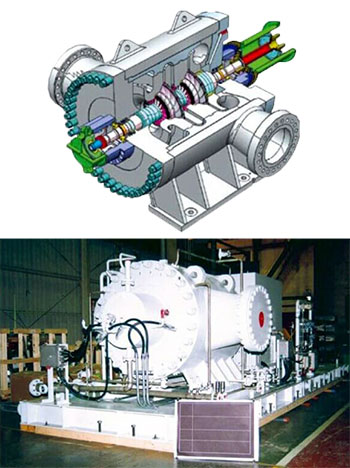

Multistage Centrifugal Compressor for Pipeline

This type of compressor, like the previous type, has a bell-shaped Casing that includes a vertical cover for the end part. The outlet and inlet nozzles of these compressors are located in opposite directions, so they are very suitable for use in pipelines. These compressors can be used up to 100 bar pressure and are usually suitable for use in natural gas transmission lines and similar applications.