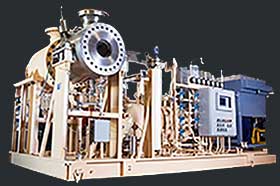

Hydrogen gas purification package of Tabriz Refinery has been defined to reduce the sulfur existing in the gasoline and gasoil produced in the refinery at the standard limit of Euro IV. Sulfur is a major impurity which exists in these fuels and based on the process defined in the refinery, sulfur is isolated from these fuels in reaction with the hydrogen produced in our package and as a result, the grade of these produced gasoline and gasoil will be at Euro IV level and as per Iran’s environmental standard.

According to the initial plan of the project the flow rate the client is supposed to deliver is equal to 61.000 Nm3/hr with the hydrogen gas mixture of 70%. In the downstream of this package, we will deliver 41,000 Nm3/hr and hydrogen with the purity of 99.5%.

We started the initial design of this package in collaboration with Air Liquid France. All stages of package design have been carried out by Havayar company in our process, piping, mechanic, electrical and instruments disciplines.

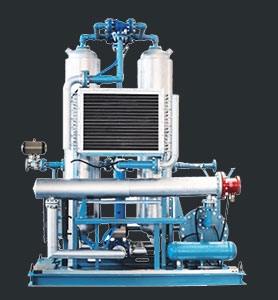

This package consists of different parts. 11 tanks with the working pressure of 18.5 barg and total weight of 2200 tons have been designed and produced. The set of piping, valves and instruments have been designed and executed on four large skids to reduce the installation time with the total weight of 2100 tons.

Considering the pressure and flow rate which has been defined for this project in Tabriz Refinery, we can claim that it is one of the biggest Hydrogen Purification projects in Iran, which has been designed, executed and installed by Havayar in best practice and with full satisfaction of the client.

With the cooperation of the foreign supplier during the project, we have approached the models of these packages and we hope to be able to design and deliver the similar Hydrogen Gas Purification Package to the customer based on the models we have obtained.