Hydrogen recovery and purification

HAVAYAR hydrogen separators/purifications operate on the Pressure Swing Adsorption process, also known as PSA Technology. This technology is based on the selective adsorption phenomena of gas molecules under pressure on the surface of highly porous and efficient adsorbent, In the case of Hydrogen generation the Adsorbent is Carbon-based Molecular Sieve(CMS). When hydrogen and carbon dioxide from the water shift reaction are used for hydrogen generation, the adsorption towers are filled with CMS.

Hydrogen recovery and purification

HAVAYAR hydrogen separators/purifications operate on the Pressure Swing Adsorption process, also known as PSA Technology. This technology is based on the selective adsorption phenomena of gas molecules under pressure on the surface of highly porous and efficient adsorbent, In the case of Hydrogen generation the Adsorbent is Carbon-based Molecular Sieve(CMS). When hydrogen and carbon dioxide from the water shift reaction are used for hydrogen generation, the adsorption towers are filled with CMS.

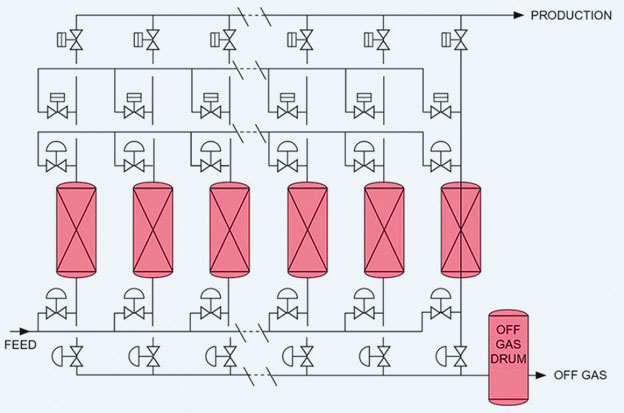

The molecules of carbon dioxide, moisture and other gases are adsorbed on the surface of CMS. hydrogen which is not adsorbed by CMS passes through the adsorption tower and is collected in a vessel.

For continuous generation of hydrogen multiple adsorption towers are provided and are operated with auto change-over valves controlled by a PLC. After saturation of one tower with carbon dioxide the process automatically changes over to the next tower and thus the hydrogen production is continuous.

The feed gas for PSA can be raw hydrogen from a wide variety of sources, including steam methane reforming, partial oxidation, cryogenic purification, methanol plant purge gases, ethylene off gas, styrene off gas, gasification and ammonia plants.

During the PSA process, the hydrogen is recovered and purified at a pressure close to the feed pressure, while adsorbed impurities are removed by lowering the pressure. The PSA tail-gas, which contains the impurities, can then be sent back to the fuel system even without a tail-gas compressor. The entire process is automatic.

HAVAYAR in participate with Global H2 PSA packagers use the most advanced adsorbents on the market with patented cycles that are optimized for recovery and productivity rates.

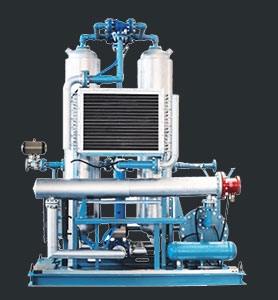

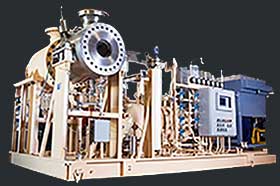

The units are made for outdoor and unmanned operation, and are designed to be both compact and fully skid-mounted

Havayar Industrial Group is a leading supplier for plant engineering and construction in partnership with most well-known international company. Our services is built on our extensive partnership expertise in the planning, project development and construction of turnkey industrial plants.

We focus on plants for the production of hydrogen and synthesis gas, oxygen and olefins as well as plants for natural gas treatment.

Advantages & Specification

Our plants meet the wide range of large, medium, and small customers’ needs

Produces hydrogen of up to 99.9999% purity

On-stream factor is typically more than 99.9%

Operates with a wide variety of feed gases

Features patented cycles and advanced adsorbents

Designed for unmanned, outdoor use

Units are compact and skid-mounted