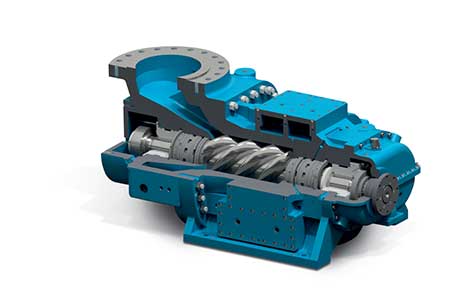

Gas screw compressors are designed and manufactured according to API 619 standard especially for high and strict safety requirements of gas compression and process cooling in oil and gas and chemical industries. The principle of working screw compressor is to draw gas into the free space between screws and pressurize it. Gas is driven through the screws into a continually contracting chamber as the rotors turn until the outlet stream achieves high pressure. This type of compressor is equipped with cast steel casings, maintenance-free tilting-pad thrust bearings, double shaft seal, rotor’s condition monitoring and sleeve bearing temperature monitoring systems which guarantee operational reliability.

- Applicable Code for design and manufacturing: API 619

- Flow rate: up to 24,000 m3/hr (20.5 MMSCFD)

- Pressure: up to 15 bar (218 PSIA)

- Power: up to 4000 kW (5264 HP)

- Speed: up to 5000 RPM

Key Specifications

This type of compressor can be designed for the compression of natural gas, refrigerants, and process gaseous hydrocarbons.

Key design features

Gas screw compressors are designed and manufactured to put in the process plants. HAVAYAR industrial group has been produced and installed numerous skid-mounted screw compressor packages. High efficiency and discharge pressure are considered as the main advantage of this type of compressors.

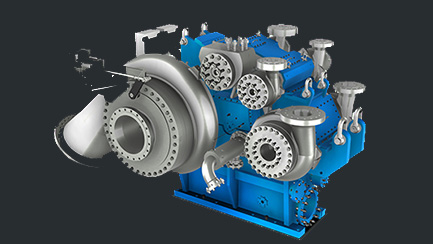

Oil Free Screw Compressor Package

Oil Free Screw Compressor Packages can be utilized in various conditions. Oil free screw compressors are available in different configurations and materials. They are able to handle with different type of gases with different conditions such as high levels of liquid, dirt and particulates. Presence of corrosive or hazardous gases or feed contamination govern the material selection in these type of compressors.

Application of Oil Free Compressor packages:

The application of Oil Free Screw Compressor packages in various processes can be listed as follows:

- Vapor recompression

- Gas Liquefaction

- Flare Gas Recovery

- Gas Gathering

- Sour Gas pressurizing

The oil free compressors are capable to produce discharge pressure of up to 45bar and differential pressure of 15bar.