Compressed air quality is a key parameter in the compressed air industry. Due to the fact that the air coming out of the compressors contains a significant amount of moisture, this amount of moisture can have destructive effects on downstream devices such as precision instruments, nitrogen generators, oxygen generators, etc. In order to reduce the cost of the harmful effects of compressed air humidity, it is recommended to use air dryer systems. Air Dryers manufactured by HAVAYAR Industrial Group can be categorized as followings:

- Refrigerant dryer

- Desiccant heated dryer

- Desiccant heatless dryer

Refrigerant Air Dryer

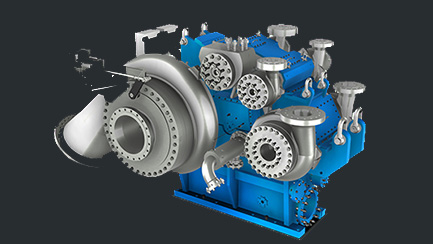

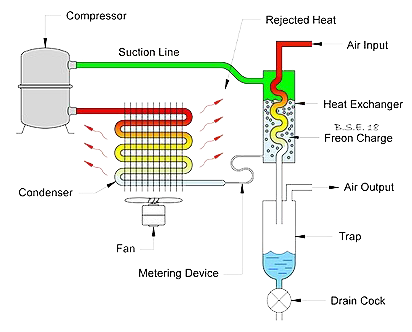

Refrigerant air dryer is the most common type of dryer in the compressed air industry. Working principle of this type of dryer is based on the compression refrigeration cycle. In these types of dryers, the refrigerant in the evaporator, absorbs sensible heat of the compressed air comes from compressor discharge which results in bringing compressed air temperature below the dew point so that the moisture in the compressed air turns into liquid droplets and which are separated in water separator. The refrigerant used in this system is selected by ISO environmental standards and needs to be recharged at regular intervals. These types of dryers are divided into two categories: air-cooled and water-cooled. For more details, in water-cooled dryers, the refrigerant in the first heat exchanger cools the water, and the chilled-water is directed to the second heat exchanger with the aim of reducing compressed air temperature below the dew point.

The most important components of this type of dryer can be listed as follows:

- Refrigerant

- Rotary compressor

- Condenser

- Evaporator

- Water-air exchanger and air-air exchanger

- Expansion valve

- Control panel

The most important advantages of using this type of dryers are as follows:

- No need for a dust filter

- Small size of the device

- Less cost of maintenance and service for this device

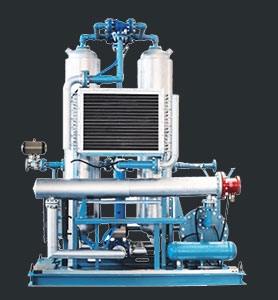

Heatless Air dryer

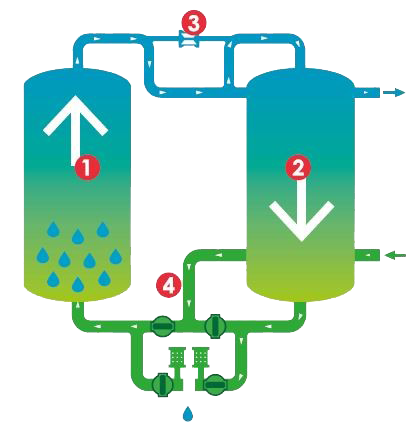

Heatless air dryer is commonly employed in some industries such as oil and gas, electronics, pharmaceuticals, food industries, etc. However, in cases where the compressed air piping is located outdoor and the 3C dew point does not meet the needs, this dryer adsorbs the moisture of the compressed air by the adsorbents. The functional schematic of heatless air dryer is drawn below. According to the figure, this dryer consists of two parallel towers fulfilled with molecular sieves. Compressed air enters the bottom of the adsorption column through the inlet line (flow 4) and flows upward after passing through the adsorbent bed. As moisture content of saturated compressed air is eliminated by the adsorbents, the dry air leaves the top of the tower. A small part of dry compressed air is used for regeneration operation of the saturated tower (flow 3) and finally after sweeping the moisture of the saturated adsorbents, it leaves the bottom of the tower (flow 2). It should be noted that, one tower is always in operational mode and the other tower is in recovery mode so that the consumer receives dry air flow continuously.

Heatless dryer consists of the following key components:

- Pressurized tower

- Adsorbent material (molecular sieve)

- Temperature, pressure and humidity sensor

- Flow control valves

- Control panel

In the field of design and production of air dryer packages (HDT), the following actions are carried out in HAVAYAR Industrial Group:

- Detailed engineering and design of the package

- Coordination and control of sub-suppliers

- Inspection and testing of consumables and equipment

- Production of all technical documents required for the project

- Holding design, layout, construction, operation and maintenance review meetings

- Pre-commissioning, commissioning and training of the employer’s forces

It is worth mentioning that this product is offered in two forms, routine and special, in HAVAYR industrial group. Routine dryers are designed and manufactured based on the manufacturer’s standards and in specific models and special dryers based on customer requests and according to their requirements and standards.

Special advantages of HAVAYAR air dryers (HDT)

- Shuttle valves applied in small sizes of dryers have the fastest and easiest function.

- These valves have maximum surface power with minimum pressure drop.

- The outside and inside of the aluminum body of the valves are protected from corrosion.

- Medium and large models are equipped with a butterfly valve to control and discharge the flow. These valves are controlled by pneumatic actuators.

- Each tower is equipped with a pressure sensor and pressure gauge.

- The noise created by the dryers during discharge period is less than 85db and within the range determined based on the health policies of the workplace.

- Microcontroller with data transfer capability.

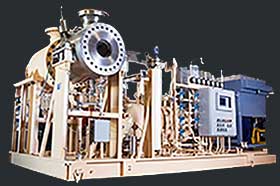

Heated Air Dryers:

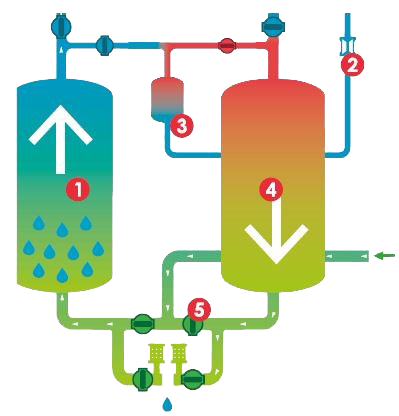

They are similar to heatless dryers, but they have a fundamental difference. For regeneration, part of the produced dry air goes through a high-efficiency external heater before entering the regeneration vessel to regenerate the adsorbents. In the figure below, item number 3 refers to the heater of this type of dryer. Considering that the rate of regeneration is directly related to the temperature of the regenerating gas, this will reduce the purge ratio and of course reduce the loss of compressed air. Although, producing additional heat by adding heater to the integrated system increase the initial cost of the heated dryer, but ultimately the reduction of the discharge rate will have a direct effect on the reduction of operating costs. The functional schematic of the heated air dryer is drawn below.

Advantages and characteristics of heated air dryers

In HHD series dryers, adsorbent materials have been used as moisture adsorbers. These highest quality materials have the following special features:

- Resistant to high temperature and environmental humidity.

- Suitable for producing dry air with a dew point above -70 degrees Celsius.

- The surface hardness of the absorbent material in them is higher than the material used in other models (this increases the life of the dust filter)

- High and useful lifetime of adsorbent materials (the lifetime of these materials is between 3 and 5 years – if used correctly).

- Adjustable temperature control system with optimal power consumption.

- Supply of heater-blower dryer without compressed air consumption for reviving the beds.

- Possibility of integrating dryer and filters on one chassis.