Natural Gas Dryer

The natural gas obtained from the ground is sutured with water vapor. The gas is cleaned and dried before it enters the distribution pipes. After this pre-cleaning, the gas may still adsorb moisture on its route to the gas point of use as the result of:

1 – Gas Water vapor diffusion and out gassing in the pipelines.

2 – Water reside in the pipelines.

Natural Gas Dryer

The natural gas obtained from the ground is sutured with water vapor. The gas is cleaned and dried before it enters the distribution pipes. After this pre-cleaning, the gas may still adsorb moisture on its route to the gas point of use as the result of:

1 – Gas Water vapor diffusion and out gassing in the pipelines.

2 – Water reside in the pipelines.

Compression of the natural gas increases the partial pressure of all gas components (including that of the water vapor) in proportion to the overall pressure. The gas witch was previously dry may reach the saturation range as the result of compression.

Condensate or, in conjunction with hydrocarbons, hydrates will from in the natural gas depending on the gas humidity. Hydrates and condensates cause problem on the natural gas refueling installation and vehicles

Liquid water is the precursor to the formation of corrosive compounds through combination with components in natural gas, namely carbon dioxide and hydrogen sulfide. The combination of corrosive agents, and the pressure cycling, caused by fuel storage container, can result in crack growth in metals and ultimately damage and failure. Also, liquid water itself can be detrimental as it may cause blockage, both liquid and solid, in the self system.

ISO 15403: 2000(E) states (paragraph 5.1):

The single most important safety requirement of compressed natural gas (CNG) fuel us a very low water dew point temperature to preclude the formation liquid water at any time.

This process utilizes the property of a porous, high-area adsorbent adsorb the water vapor molecular sieves as the adsorbent, and these sieves adsorb only water vapor molecules, thus retaining the gas composition unchanged.

GENERAL DESCRIPTION OF REGENERATION DRYER

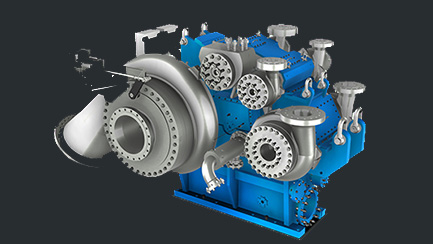

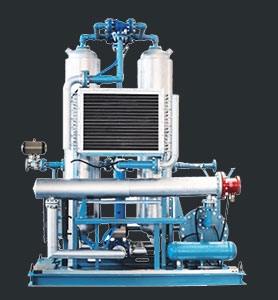

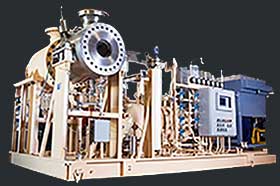

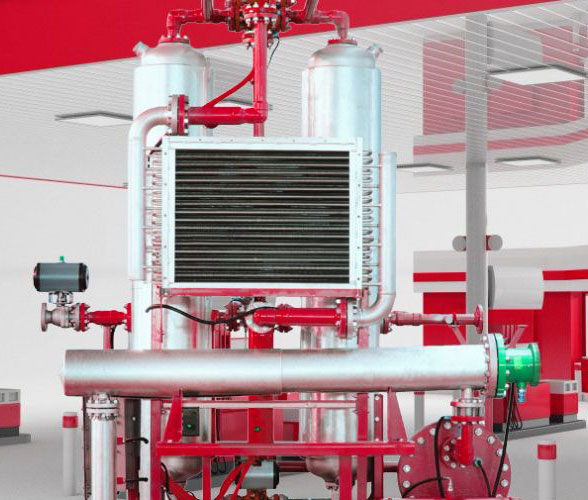

The skid mounted twin tower, external-heated, fully automatic, closed-loop regenerative dryer is used for the purpose of dehydration natural gas and provide dryer and oil free gas.

Havayar dual tower regenerative natural gas dryer is included the latest technology and safety features. It’s equipped with two desiccant filled Pressure Vessels, Electrical heater, Air cooled, Heat exchanger, Pre-after filters and can work with two working mode:

AUTO DEW SWITCHING MODE

FIXED TIME CYCLE SWITHING MODE

The package is installed upstream to the compressor and can effectively protect the compressors from oil, water, and dust contaminations.

STANDARD AND CODE

All dryers have been designed based on manufacture standard and in conformity with the latest edition of blew standard:

- ASME Sec. VIII for pressure vessel design

- ISA standard for instrumentation

- IEC & NFPA 70 standard for electrical components.

- API 661 standard for heat exchangers

- ASME B31.3 & B31.8 for piping

- GPSA for process

Can be built to specific requirements such as the Chinese and Malaysian pressure vessel cods

Havayar Dryer Features

Maximum Efficiency

Low running cost, low pressure drop and steady dew point are considered through careful design and manufacture.

Easy Installation

All parts and sub equipment’s are completely assembled on the dryer bed and are shipped ready for installation with no assembly work required on the site.

Easy start up, operation and maintenance

Completely automated control equipment which starts after pushing operation button, thereafter it can be controlled from a control panel, with all necessary interlocking devices provided to prevent trouble arise from operators or other disturbance. Routine inspection and maintenance are facilitated by optimum arrangement.

Minimum Pressure Drop

The unique design of the regeneration system ensures the pressure stability during the heating and cooling regeneration processes.

Catalogue